In a Transformation analysis, you simulate the conversion and transportation of energy forms from the point of extraction of primary resources and imported fuels all the way to the point of final fuel consumption. As with your demand analyses, alternative scenarios can be used represent different future Transformation configurations reflecting alternative assumptions about policies and technologies.

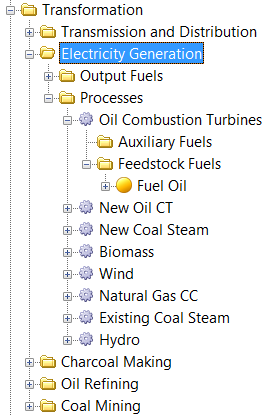

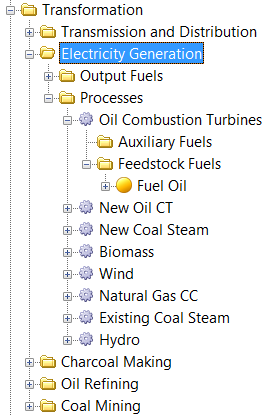

The general data structure of a Transformation analysis is shown on the right.

Modules:

Under the top Transformation branch you can add any number of modules.

A module is a branch representing an energy conversion sector such as

electricity generation, oil refining, district heating, charcoal making,

transmission and distribution, etc. Note that the ordering of modules

will affect your calculated results. Energy flows from the primary resources

listed at the bottom of the screen up through each of the Transformation

modules, until it is eventually consumed in the Demand devices listed

in your Demand analysis. At the module level, you also define the Settings

for simulating the operation of the energy industry, such as whether you

wish to specify capacity restrictions, and how you want to simulate the

dispatch of different processes.

Modules:

Under the top Transformation branch you can add any number of modules.

A module is a branch representing an energy conversion sector such as

electricity generation, oil refining, district heating, charcoal making,

transmission and distribution, etc. Note that the ordering of modules

will affect your calculated results. Energy flows from the primary resources

listed at the bottom of the screen up through each of the Transformation

modules, until it is eventually consumed in the Demand devices listed

in your Demand analysis. At the module level, you also define the Settings

for simulating the operation of the energy industry, such as whether you

wish to specify capacity restrictions, and how you want to simulate the

dispatch of different processes.

Processes: Below

each module, you can create any number of processes. Processes represent

the individual technologies that convert energy from one form to another

or transmit or distribute energy, such as individual power plants or groups

of power plants. Processes are grouped under a single category branch

labeled "Processes". For each process, you define technology

data such as capacities, efficiencies, capacity factors, capital and operating

and maintenance costs.

Processes: Below

each module, you can create any number of processes. Processes represent

the individual technologies that convert energy from one form to another

or transmit or distribute energy, such as individual power plants or groups

of power plants. Processes are grouped under a single category branch

labeled "Processes". For each process, you define technology

data such as capacities, efficiencies, capacity factors, capital and operating

and maintenance costs.

Feedstock

Fuels: Each process has one or more feedstock fuels. Feedstocks

are the fuels converted within the process itself, such that the efficiency

of a process is defined as the ratio of the total energy content of all

output fuels produced by the process divided by the total energy content

of all feedstock fuels consumed.

Feedstock

Fuels: Each process has one or more feedstock fuels. Feedstocks

are the fuels converted within the process itself, such that the efficiency

of a process is defined as the ratio of the total energy content of all

output fuels produced by the process divided by the total energy content

of all feedstock fuels consumed.

Auxiliary

Fuels: Each process

can optionally have one or more auxiliary fuels. Auxiliary fuels are used

to represent subsidiary or own-use energy consumption in a Transformation

process, such as electricity used in an oil refinery or the own-use of

electricity in a power plant.

Auxiliary

Fuels: Each process

can optionally have one or more auxiliary fuels. Auxiliary fuels are used

to represent subsidiary or own-use energy consumption in a Transformation

process, such as electricity used in an oil refinery or the own-use of

electricity in a power plant.

Output

Fuels: Each module has one or more output fuels. The module's

processes are dispatched to try and meet any requirements for its output

fuels. You can choose either to specify each fuel's share of the total

energy output from a module, or to have LEAP calculate output shares on

the assumption that they are proportional to the requirements on the module.

NB: note that output fuels are specified for the module as a whole. In

general, you can specify separate outputs for each process. However you

can optionally specify a single co-product fuel (e.g., heat) , which can

produced by only certain processes. Go to the module properties screen

to specify a coproduct fuel.

Output

Fuels: Each module has one or more output fuels. The module's

processes are dispatched to try and meet any requirements for its output

fuels. You can choose either to specify each fuel's share of the total

energy output from a module, or to have LEAP calculate output shares on

the assumption that they are proportional to the requirements on the module.

NB: note that output fuels are specified for the module as a whole. In

general, you can specify separate outputs for each process. However you

can optionally specify a single co-product fuel (e.g., heat) , which can

produced by only certain processes. Go to the module properties screen

to specify a coproduct fuel.

Transformation calculations are driven by the results of the your Demand analysis. Succeeding modules satisfy one set of fuel requirements but create another set of input requirements. (for example, an electricity generation module meets requirements for electricity but creates additional requirements for its own feedstocks. The final outcome of calculating all modules is a set of requirements for primary resources (fossil-fuel or renewable) and for imports of fuels into the Area .

There are four basic steps involved in setting up a Transformation model:

Identify Modules to Include: A module represents an energy industry or sector such as electricity generation, oil refining, district heating, charcoal production, or electricity transmission and distribution. You will want to include all current modules, and, depending on the time-scale of your analysis any planned or potential future modules, even those that may not yet be significant, such as cogeneration, biofuel production, and perhaps even hydrogen production. One starting point would be to examine the rows in the conversion section of an energy balance to identify the modules for the area you are studying. Alternatively, you can work from the module structure which exists in LEAP's default data set. By editing the tree in your LEAP area, you can change the default module structure. Modules can be added, deleted or changed to fit your study's requirements.

Sequence Modules: Make sure you arrange modules on the tree into a correctly ordered list. The ordering of the modules reflects their position in the sequence of energy flows through an area. Thus, transmission and distribution modules are normally placed near the top (close to Demand), conversion modules such as electricity generation are placed in the middle, and primary resource extraction modules are placed at the bottom of the list.

Set Module Properties: In setting-up each module, it is important to consider how each module is to be represented. For example, whether you wish to model capacity constraints, or whether you want to assume that a module can always meet its requirements. Modules without capacity restrictions require less data and are generally easier to set-up and debug, but may not accurately reflect real-world situations.

Determine Level of Detail and Enter Data: Another important consideration is the level of detail to include in each module. Each module is divided into one or more processes. A process describes an individual technology or a group of technologies. You need to decide whether you wish to include each individual technology (e.g. each power plant) or whether you want to model groups of similar technologies as a single process (e.g. all diesel peaking plants). While there are no particular limits on the number of processes you can include in each module, bear in mind that the more processes you include, the more complex your model will be to set-up, interpret and debug and the slower your calculations will be. For each process, you enter technical data such as capacities, efficiencies, and output fuels. You can also enter cost data, and describe the environmental loadings of feedstocks and auxiliary fuels through links to TED .

The data you need to enter for a Transformation module, depend on the properties you set for each module, and in particular whether or not you choose to enter capacities and costs, and which dispatch rule you specify. Use the Module Properties screen to set these options.