Process Dispatch Calculations

See also: Transformation Calculations

During Transformation calculations, LEAP dispatches the processes in each module to try and meet the requirements for energy on the module. Depending on the dispatch rule you choose (specified on the Module Properties screen), different calculation algorithms area used to calculate how much of each process is dispatched (i.e. the energy outputs from each process).

Two specialized dispatch rules ("Dispatched by Merit Order" and "Dispatched by Running Cost") are available for simulating the dispatch of processes (typically electric power plants) in order to meet both the peak power requirements and the energy requirements on a module. For information on the calculations for these two dispatch rules, see topic: Dispatching Processes on a Load Curve.

The rest of this section focuses on the remaining dispatch rules.

The first step in dispatching the process is to calculate the share of energy outputs for each process. The algorithms for this calculation are listed in the following table:

Dispatch Rule |

Algorithm |

Process Shares |

None: Share of output is explicitly specified using the "Process Shares" variable for each branch. |

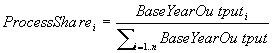

In Proportion to Base Year Output |

Note if the calculated module requirements do not match the sum of specified base year outputs for a module, then the calculated base year outputs for each process will not match the data entered for "Base Year Outputs". An error message will be displayed if this situation occurs. The most likely cause is that your energy demand data and/or your transmission and distribution data are not consistent with the data you entered for base year outputs. Check all three of these categories of data to find out if there is an error in data entry, or if the two sources of base year data are inconsistent. |

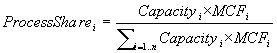

In Proportion to Available Capacity or Run to Full Capacity |

|

Once the share of output from each process has been calculated, LEAP calculates the actual energy output from each process. In cases where you have chosen to capacity-constrain processes (by checking "Capacity data" on the Module Properties screen), LEAP will compare the proportions of output shares and available capacities (capacity x availability) in order to identify the process in each module that constrains overall output from the module. This information is in turn used to calculate the total capacity constrained outputs from each process.

Finally, this information is used to calculate the input fuels required by each process, and consequently the costs, benefits and environmental loadings of each process.