Topic: Cement Industry, Environmental effects, TED database Subscribe | Previous | Next

Hello, for the production of cement in my country Petroleum coke and End of Life tires are used.

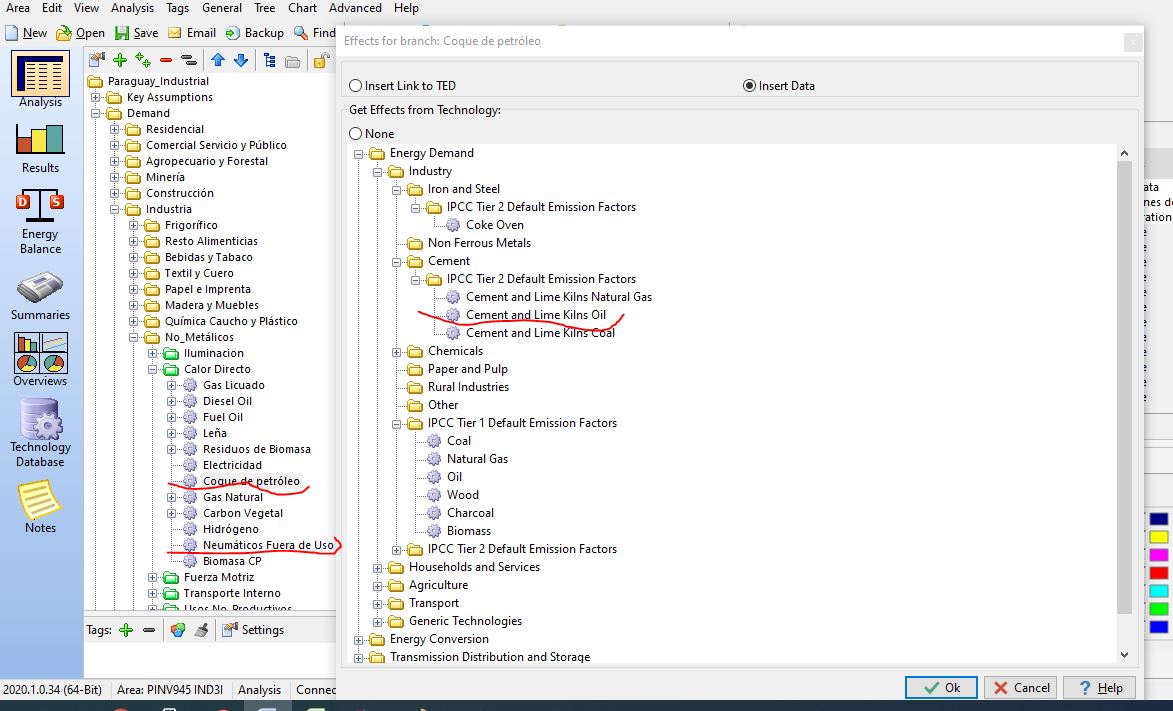

For the Environmental Effects of Petroleum coke, is it correct to select: Industry, Cement, IPCC Tier 2 Default Emission Factors, cement and lime kilns Oil?

For the Environmental Effects of End of Life Tires, which one do I use?

Thanks.

1 Like I'm not sure Estela. I would guess that tires have very different emissions factors from burning standard oil products. I'd recommend doing some basic research on this issue.

Thanks. I'll do my research on the tires.

For the Environmental Effects of Petroleum coke, is it correct to select: Industry, Cement IPCC Tier 2 Default Emission Factors, cement and lime kilns Oil? or is similar to: Industry, IPCC Tier 2 Default Emission Factors, Coke Oven

1 Like Dear Estela and Charlie,

GHG emissions from cement production are a little bit tricky. Cement production is usually divided into two steps (in terms of modelling): firstly the clinker production, which is a sort of pre-cement, and afterward the cement production stage, which involves mixing the clinker with gypsum in a cement mill. The second step, the cement milling process, consumes uniquely electricity so emissions in such process come from the electricity grid (so, if considered, they are indirect GHG emissions).

Regarding the direct GHG emissions, those come from clinker production. Such process involves (apart from pre-processing and treatments of material and flue gases which there is an electricity consumption) high-temperature needs (the material input is limestone (in Spanish, piedra caliza), so the process to transform such limestone into clinker happens at 1400 Celsius so it is required to combust something. In the past, it was frequent to burn fossil fuels, mostly petroleum coke or coal, but this has been changing quickly due to the GHG emissions concerns. Accordingly, a lot of European cement plants began to burn a lot of waste in the ovens. The use of waste is a sort of tricky solution since cement producers argue that GHG emissions are then zero or almost zero, since the fuel is a waste, so its emissions already happened during the lifetime of the product (when it was). For instance, in Spain a lot of cement plants make use of used tires as energy fuel.

Answering your question:

- In a cement plant there are 2 types of GHG emissions: ones coming from the combustion of the fuel to produce the heat for the oven (in your case, petcoke), and some others from the limestone transformation into clinker (these emissions are "material emissions" and they are difficult to avoid).

- If you want to use a unique emission factor associated to cement production you must consider this to avoid bias. Namely: to use a "holistic" emission factor at plant level or to consider two emission factors associated one with energy activity level and the other with the material activity level.

- In here you can find more info: https://ghgprotocol.org/sites/default/files/co2_CSI_Cement_Protocol-V2.0_0.pdf

Hope this could help.

Regards,

Diego

1 Like Besides, all the examples you can find in TED database which refer to "oil" are closer to the emissions of diesel or gasoline or other liquid fuel than petroleum coke.

In your case, petcoke could be associated with technologies consuming coal, since both are solid fossil fuels and their emissions are closer than those from liquids.

This is not a rule but it is a sort of compromise solution.

Besides: 40% of GHG emissions from cement production come from burning the fuels (energy emissions)

and 60% of GHG emissions come from the transformation of the limestone into clinker (material emissions)

Nowadays, the emission factor for a cement plant ranges from 0,65 to 0,95 tonnes of CO2 per tonne of cement produced.

https://ec.europa.eu/clima/system/files/2016-11/global_3_en.pdf