Topic: Error optimizing with NEMO Subscribe | Previous | Next

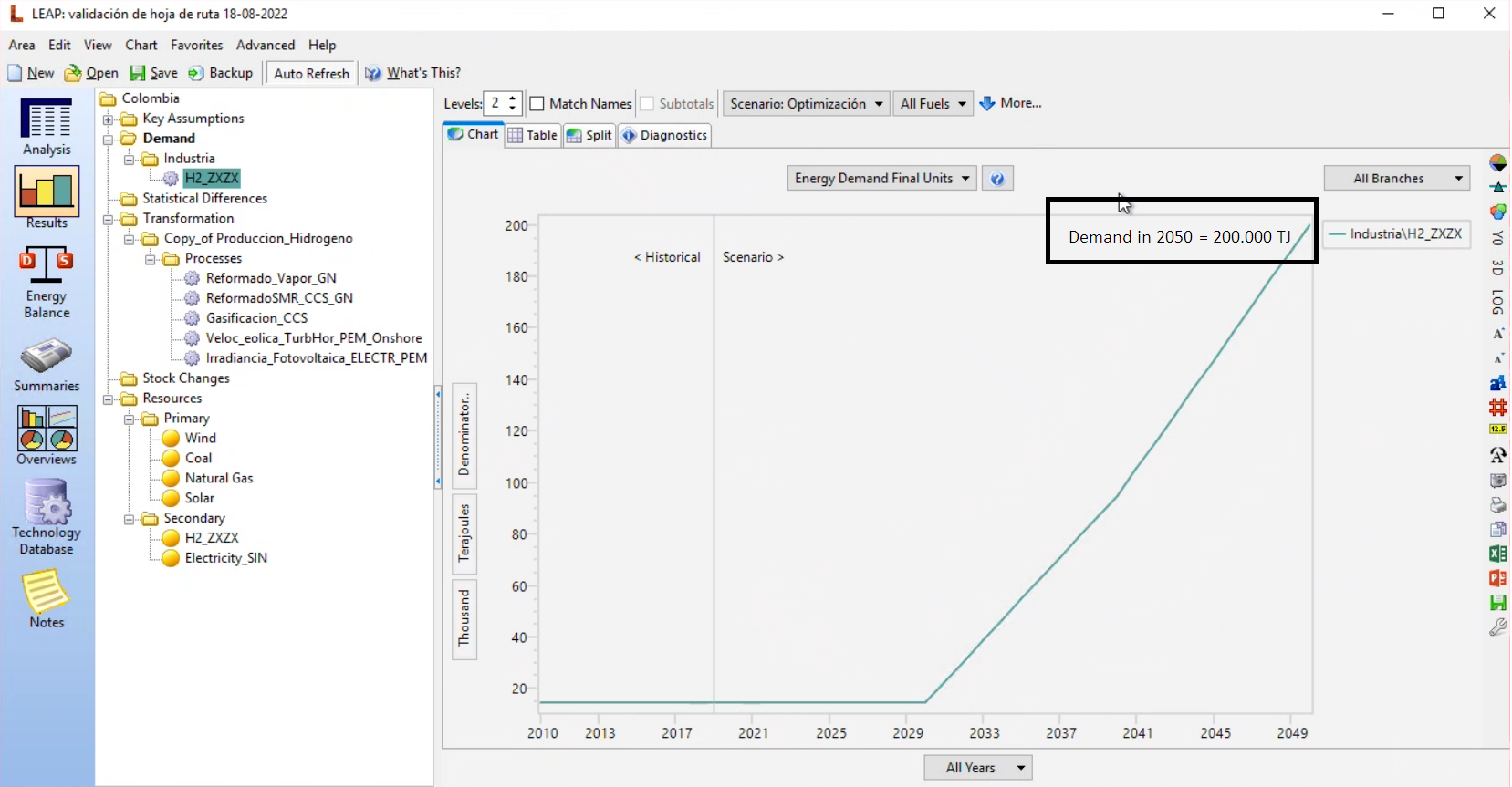

We are trying to

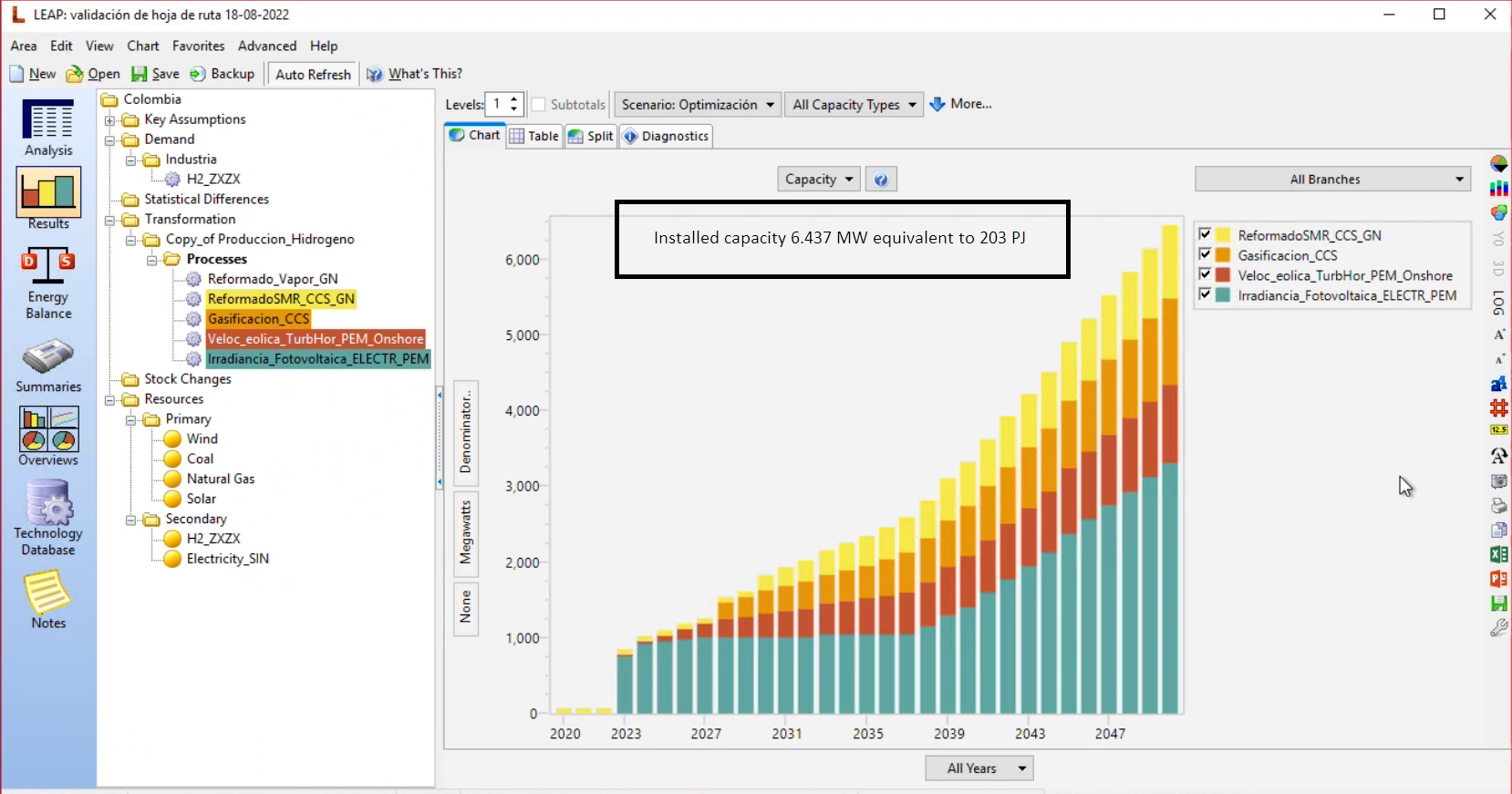

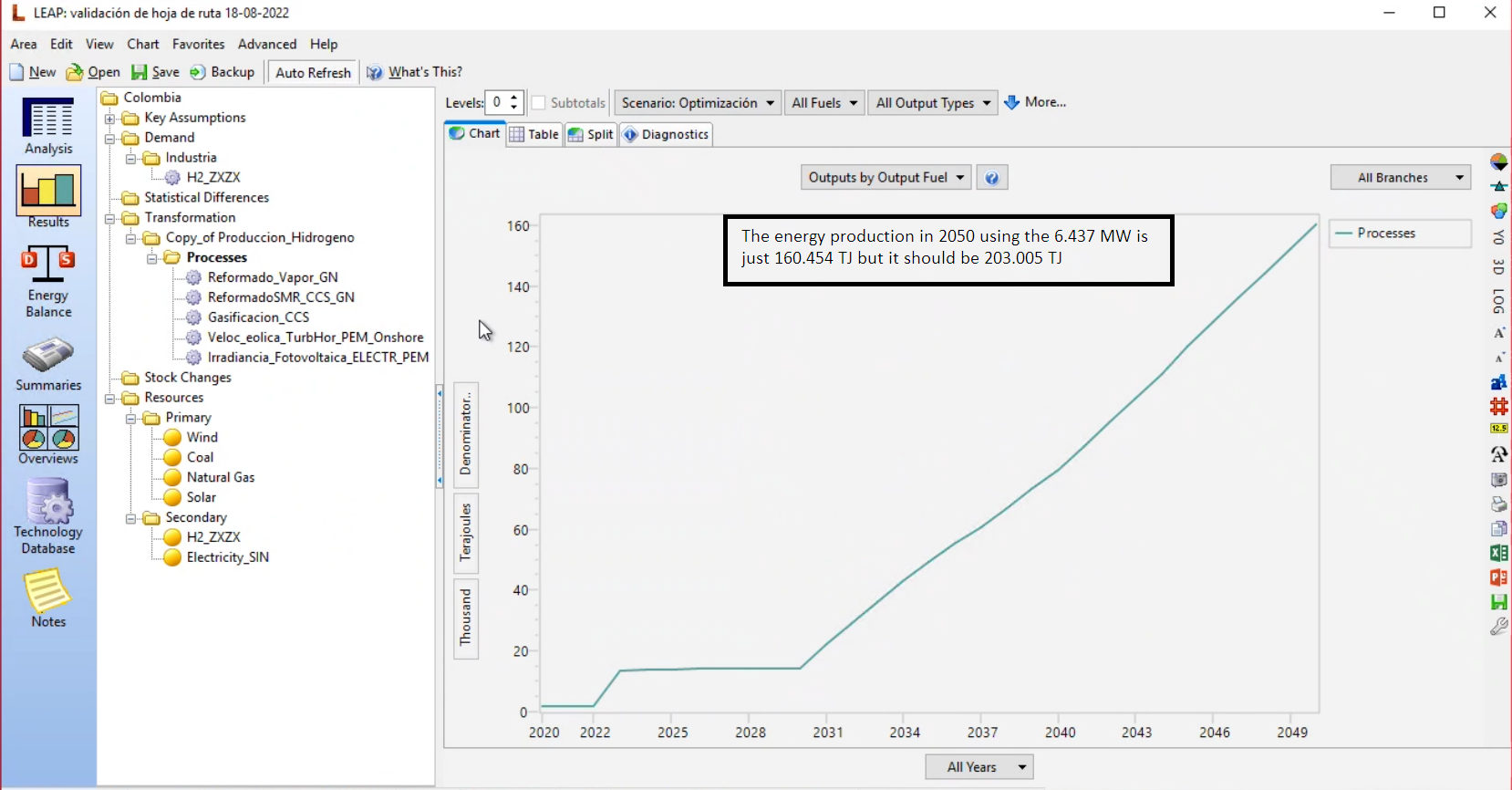

optimize a transformation module, but NEMO is underusing the install

capacity. For example, the demand in 2050 is 200 PJ and the installed capacity-optimized

is 6437 MW which potentially generates 203PJ. However, in the figure of the output-by-output

fuel, you will see that just 160 PJ are generated, and the figure of the actual

availability shows that in most of the technologies the parameter of Actual availability

is under 100% even when is not reaching the energy demand.

To solve this, we have

already:

Increase the cost of importing

the fuel at least 10.000 times (making it impossible to import the fuel without

enormously increasing the total cost)

Set unlimited reserves of the feedstock fuels and decrease their price (just to verify if the

Actual availability of the plants increase)

We want to know:

Is there a way to

manually set the Actual availability?

Why is not using the

technologies with an availability of 100% and instead is still proposing to import the unmet requirements?

(Even with the inflated cost of importing)

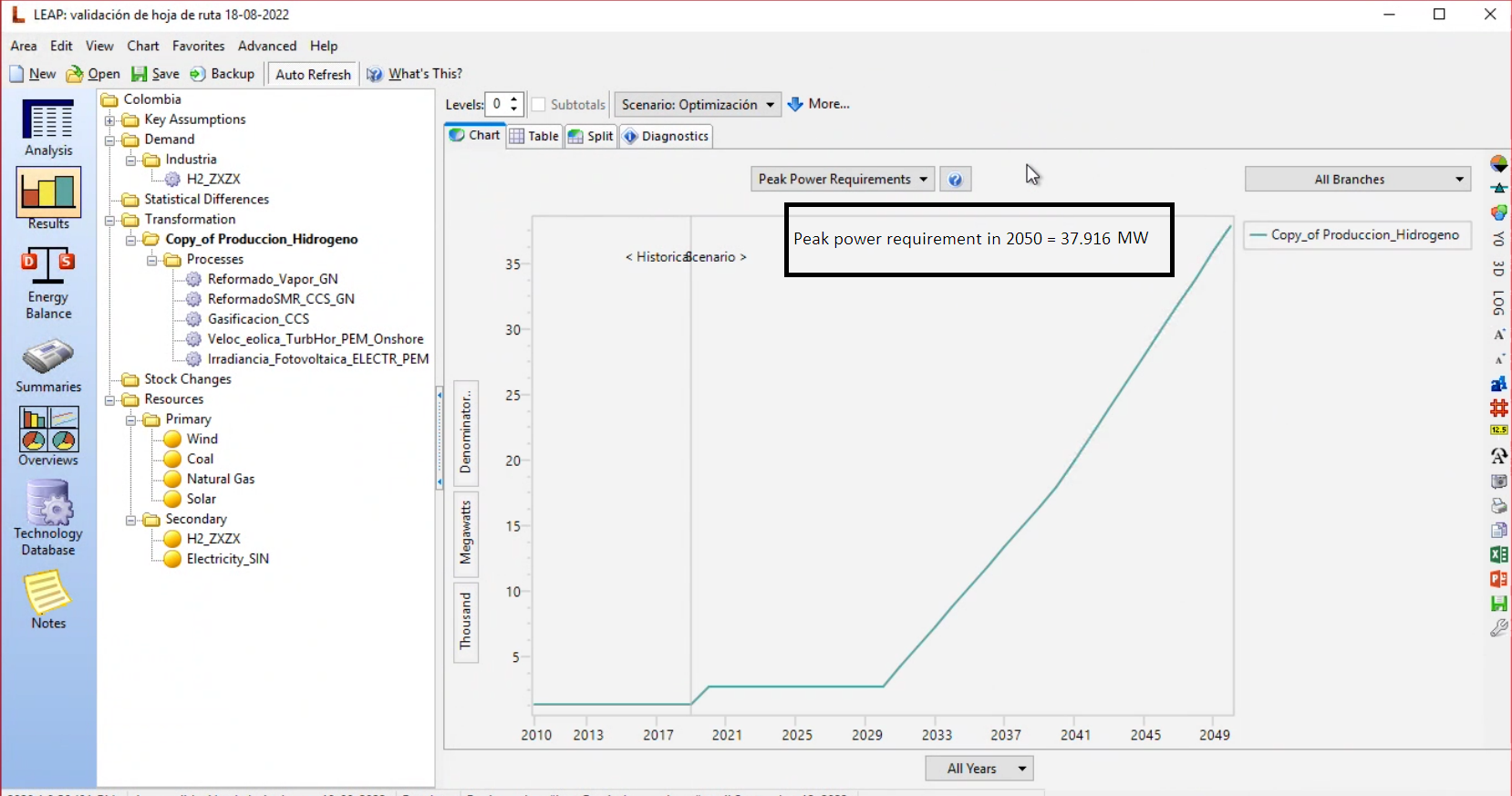

Why is proposing a peak

power requirement that is overestimated (in the figure of peak power requirement

you will see that is proposing almost 6 times the calculated 6437MW of install

capacity)

Hi, John –

You've posed some interesting questions, but they can't all be answered conclusively with the information you provided. Let me take each of them in turn.

First, regarding why you're not seeing the total production and actual availabilities you expect. In this case, we're missing a key piece of information: the maximum availabilities of your transformation processes. Maximum availability is a constraint on actual availability and output; so depending on how it's set in your model, it could explain the production and actual availabilities you're seeing. (On a related note, you say the installed capacity in the model could generate 203 PJ. According to my calculations, that would only be possible if the maximum availability of all capacity were about 100%. This is an unrealistic value for most processes, though.)

Third, regarding the peak power requirement. Again, some key information is missing, including the peak load ratio and planning reserve margin for your optimized module. Depending on how these are set, they could be allowing the result you're seeing. I suggest reviewing LEAP's documentation on these variables and making sure they're specified correctly for the problem you're analyzing.

Finally, I'd like to clarify a couple of other points you raised. The first is that the availability of feedstock fuel reserves doesn't affect optimization in LEAP. This is because LEAP doesn't provide NEMO information on the amount of reserves. Instead, it writes an assumption to NEMO that all input fuels used in an optimized module are available in unlimited amounts at the fuel prices specified in the module.

The second is that the cost of imports (here I'm assuming you're talking about the import cost variable in the Resources branch) also doesn't affect LEAP optimization. Again, this is because this information isn't provided to NEMO.

My bottom-line recommendation, then, is to have another look at the maximum availability, planning reserve margin, and peak power requirement variables to see if they're inducing these results.

Thanks,

Jason

.png)